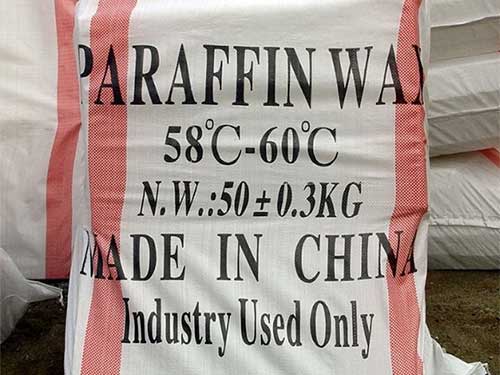

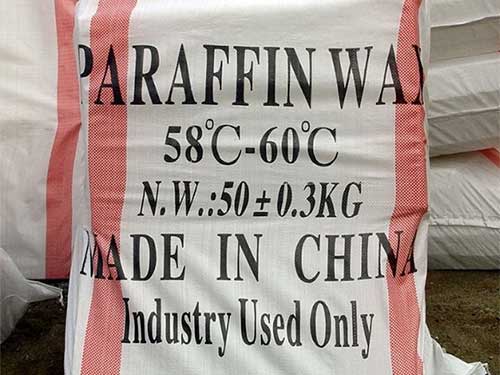

Product name��Fully refined paraffin wax58-60

Other name��paraffin wax

CAS NO.��8002-74-2

HS Code: 2712200000

Appearance: White Slab, Granular

Melting Point: 58-60

Oil Content (%): 0.5

Package: 25kg/50kg woven bag with inner plastic lining.

Usage: Usded in candle, pastic , coating , sealing , adhesive ,rubber.

Output��5000MT/year

Property:

Paraffin waxes are separated from crude oil during the production of light (distillate)

lubricating oils. These waxes are categorized by oil content and the degree of

refinement. The crudest versions fall into the slack wax category and contain between

5% to 20% oil. Next on the step of refinement are scale waxes containing between 1%

to 5% oil. The highest grade of refinement is the fully refined wax. Fully refined

paraffin waxes contain less then 0.5% oil and have been hydrotreated or clay treated to

remove impurities and color. The resulting waxes are water clear, odor free, and

normally food grade.

Specification:

Fully Refined Paraffin Wax | 56/58 | 58/60 | 60/62 | 62/64 | 64/66 |

Melting Point ��C | 56-58 | 58-60 | 60-62 | 62-64 | 64-66 |

Oil Content %(m/m) | 0.5max | 0.5max | 0.5max | 0.5max |

|

0.5max |

|

|

|

|

|

Colour | 28 min | 28 min | 25 min | 25 min | 25 min |

Light Stability | 4 max | 4 max | 5 max | 5 max | 5 max |

Needle Penetration (25��C)1/10mm | 18 max | 18 max | 16 max | 16 max | 16 max |

Odor | 2 max | 2 max | 2 max | 2 max | 2 max |

Application:

1.Candle production like molding, dipping, drawing, extrusion/pressing.

2.Polishes to improve buff ability, to provide solvent binding and solvent retention

properties.

3.Rubber and Tires as mould release agents, plasticizers and lubricants in rubber

blends.

4.Cosmetics and Pharmacy to act as base component in various formulations.

5.Paper Coating formulations covering packaging of food and non food articles.

6.Hot Melt Adhesives as cost-competitive blend component.

7.Chemical Industry as processing agents, raw materials, components.